Serving Indonesia with Cutting-Edge Innovation

At PT. Kahramann, we are committed to delivering the highest standard of cleaning and pipeline inspection services across Indonesia. Our primary mission is to ensure the integrity, safety, and operational efficiency of pipeline systems that are vital to the nation's infrastructure. Backed by years of industry experience and expertise, we utilize cut ting-edge technologies and advanced techniques to meet the ever-evolving demands of our clients. We recognize that the challenges facing Indonesia's pipeline networks require both innovative solutions and a deep understanding of local conditions. Our unwavering commit ment to innovation, combined with a focus on safety, quality, and efficiency, makes PT. Kahramann a trusted partner for pipeline owners and operators seeking reliability and long-term success

PRODUCT

INTELLIGENT PIG

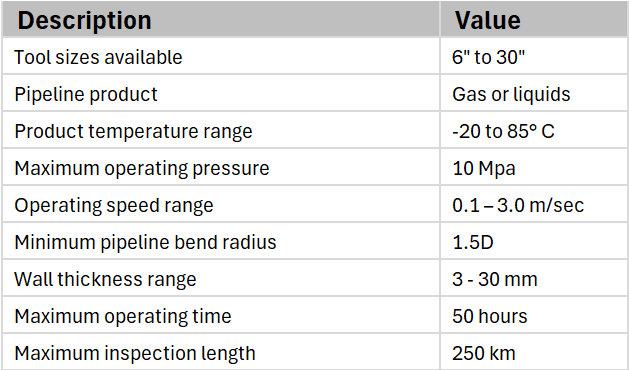

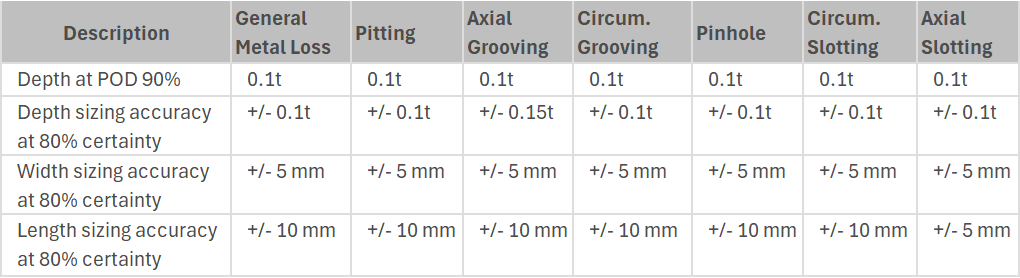

1. MAGNETIC FLUX LEAKAGES ( MFL)

Intelligent Pig is a pigging tool that is used for the inspection process on pipeline using various instrumentation and sensors that are inserted into the pipeline to detect, measure, record the size and position of pipeline anomalies or damage, for example, internal or external corrosion, dents, cracks, welds or differences thickness and so on. Then the data will be recorded and can be analyzed by engineers and technicians, to determine the integrity of the pipeline and report thecondition of the pipeline.

This technology uses a metal brush to connect a permanent magnet to the pipe wall to magnetize the pipe wall due to the flow of magnetic flux to the pipe wall which will move from the north pole to the south pole of the magnet.

When there is an anomaly or inhomogeneity in the pipe wall, it willcause interference with the flow of the magnetic flux. Then the sensor will measure and find out the pattern of the magnetic flux disturbance. From this, the anomaly or inhomogeneity in the pipe walls both externally and internally can be searched, detected, characterized, and measured. And the odometer will be recorded where is the anomaly located in the pipeline

This technology uses a metal brush to connect a permanent magnet to the pipe wall to magnetize the pipe wall due to the flow of magnetic flux to the pipe wall which will move from the north pole to the south pole of the magnet.

When there is an anomaly or inhomogeneity in the pipe wall, it willcause interference with the flow of the magnetic flux. Then the sensor will measure and find out the pattern of the magnetic flux disturbance. From this, the anomaly or inhomogeneity in the pipe walls both externally and internally can be searched, detected, characterized, and measured. And the odometer will be recorded where is the anomaly located in the pipeline

APPLICATIONPipeline inline inspection, to detect internal and external anomalies on the pipeline applicable for both gas pipeline system and liquids pipelines system

|

BENEFIT

|

2. CALIPER PIG

GEOMETRY

During the construction process or its operation, a pipeline may undergo physical deformation such as dents, bent, buckles, gouges, etc. These physical deformations can be the initiator of pipeline failures such as cracks or raptures. And the physical deformation results in a change/reduction in the diameter of the pipeline.

This reduction in diameter can limit the movement of PIG in the pipeline. This is one of the things that must be considered when running large and heavy PIG equipment such as the ILI PIG with MFL technology, where changes in pipe diameter can cause the PIG to get stuck, and can completely clog the pipe.

So before doing a pipeline inspection with the ILI PIG tool, it is necessary to find and analyze whether there is any physical deformation in the pipeline. And this is the main purpose of the ‘caliper’ pig or ‘geometry’ pig.

This reduction in diameter can limit the movement of PIG in the pipeline. This is one of the things that must be considered when running large and heavy PIG equipment such as the ILI PIG with MFL technology, where changes in pipe diameter can cause the PIG to get stuck, and can completely clog the pipe.

So before doing a pipeline inspection with the ILI PIG tool, it is necessary to find and analyze whether there is any physical deformation in the pipeline. And this is the main purpose of the ‘caliper’ pig or ‘geometry’ pig.

APPLICATION |

BENEFIT |

|

Detect geometric anomalies/physical deformations such as

|

|

UTILITY PIG

Our Utility Pigs can be classified into two groups based on their basic purpose namely.

|

|

3. FOAM PIG

|

Foam pigs are also known as Polly-Pigs. foam pigs are molded from poly urethane foam and are grouped into 4 types based on the density of poly urethane foam used to mold it,

|

In addition to the foam pig provide additional finish configurations that are permanently bonded to the foam pig surface to suit specificapplication requirements, namely :

|

APPLICATION |

BENEFIT |

|

|

4. MANDREL PIG

Mandrel pig is pigging equipment with long-term use. The mandrel itself is a tubular component made of steel, which acts as the body of the pig with additional sealing and cleaning components that can be assembled according to project needs, on the steel body. Here are the components of our mandrel pig, which can be selected according to the desired application

|

|

APPLICATION |

BENEFIT |

|

The Mandrel Pig limitless configuration makes it a goodchoice for :

|

So basically The mandrel pig can be either be a cleaning pig, or a sealing pig, or a combination ofboth. And the other advantage of mandrel pigs is the ability to replace the wearing components (cups, discs, blade, etc.) With new components, with the same or different configuration.

|

5. Bi-Directional PIG

BIDI

Bi-Di pigs are the most commonly used pigs in the oil and gas industry. These pigs have excellent sealing qualities, and their bi-directional design allows the pig to run in either direction in the pipe line. The design of bi-directional [bidi] relies upon two parts, first is the “support” or “guiding” discs that are typically 1% or 2% less than that of the internal diameter [ID] of the pipeline. And the second part is “sealing” discs, which are larger than the internal diameter [ID]

Standard bi-directional pigs [bidi pigs] include four sealing discs, which are used for high perfor mance sealing as well as drive discs together with two support discs (or commonly call “guiding disc”) in two packages to ensure equal support. There are two main desain for our standard bidi pig:

Standard bi-directional pigs [bidi pigs] include four sealing discs, which are used for high perfor mance sealing as well as drive discs together with two support discs (or commonly call “guiding disc”) in two packages to ensure equal support. There are two main desain for our standard bidi pig:

APPLICATION

Bi-directional pigs are used in pipeline construction for hydrostatic testing or water displacement, as well as removal of debris and product separation. These pigs can also be used as a cleaning pig or batching pig.

BENEFIT

|

|

6. Gauging PIG

Gauging Pig is a pig used to check whether there is a reduction in the internal diameter of thepipe. Basically a gauging pig is just a utility pig with a gauging plate attached to it

This “gauging plate” is a component/part in the form of a circular soft aluminum material, the way it works is that the gauging plate will deform if there is a reduction in the pipe diameter exceeding the minimum pipe diameter or the diameter of the gauging plate.

The diameter of the gauging plate is 95% of the nominal inside diameter of the pipe. This is intended to allow/tolerate some ovality of pipe that the pipe may have under unpressurized conditions as well as for any ovality caused by field bends

Gauging is a simple form of ‘geometry’ or ‘caliper’ PIG, the difference is that gauging pig only provides information that there is or is no deformation of the pipeline diameter beyond the minimum diameter for PIG Passage, but does not provide information of location and how much is the deformation was detected and the shape and size of the deformation as given by ‘geometry’ or ‘caliper’ PIG

The diameter of the gauging plate is 95% of the nominal inside diameter of the pipe. This is intended to allow/tolerate some ovality of pipe that the pipe may have under unpressurized conditions as well as for any ovality caused by field bends

Gauging is a simple form of ‘geometry’ or ‘caliper’ PIG, the difference is that gauging pig only provides information that there is or is no deformation of the pipeline diameter beyond the minimum diameter for PIG Passage, but does not provide information of location and how much is the deformation was detected and the shape and size of the deformation as given by ‘geometry’ or ‘caliper’ PIG

We're Here to Secure Your Pipe's Future Find Innovative In-Line Inspection Services

Advanced Cleaning Solutions for Pipeline LongevityOne of our core services is pipeline cleaning, designed to remove deposits such as debris, corrosion, paraffin, scale, and other obstructions that can accumulate over time and impede pipeline operations. A clean pipeline ensures smoother operations, reduces pressure loss, and significantly minimizes the risk of costly breakdowns or failures.

We understand that each pipeline is unique, and that is why we tailor our cleaning strategies to suit the specific conditions and challenges of every project. By using state-of-the-art pigging technology and innovative cleaning tools, we effectively tackle even the most complex pipeline conditions. Whether for crude oil, natural gas, water, or other industrial pipelines, our cleaning techniques are designed to restore the full operational capacity of the pipeline. What sets us apart is our ability to deliver these services with locally produced, custom-built equipment, allowing for quicker delivery times, reduced lead times, and the ability to modify tools as required for each project. Our focus on efficiency extends beyond simply cleaning the pipeline—we also look at optimizing the overall flow capacity and performance of the system, helping to extend the lifespan of the asset while reducing operational risks. The proactive maintenance approach we imple ment helps to prevent pipeline degradation and enhances long-term performance |

Innovative In-Line Inspection Services for Proactive MaintenanceIn addition to cleaning, PT. Kahramann excels in providing cutting-edge in-line inspection services. This is a critical service designed to identify and assess internal anomalies within pipelines without interrupting operations, thus maintaining continuous flow while performing inspections. Through our in-line inspection technology, we can conduct a detailed internal assessment of the pipeline’s condition, identifying corrosion, wall thickness, metal loss, cracking, and other integrity-related issues.

Our inspection tools, including Magnetic Flux Leakage (MFL), Ultrasonic Testing (UT), and Geometry Tools, provide highly accurate and com prehensive data on the internal health of pipelines. These advanced tools allow us to detect even minor anomalies, ensuring potential prob lems are addressed before they become major issues. By identifying these concerns early, our clients can plan for necessary maintenance, minimizing downtime and avoiding the need for costly emergency repairs. |

Commitment to Safety, Quality, and Industry LeadershipSafety is at the heart of everything we do. We adhere to the strictest safety protocols and guidelines to ensure the pro tection of our workforce, our clients' assets, and the environment. All of our operations are carried out by highly trained professionals who are not only experts in their field but also certified to the highest industry standards.

We take great pride in our team's dedication to quality. Whether it's delivering cleaning solutions or conducting in-line inspections, we main tain a rigorous focus on ensuring that every project is completed to the highest standards of precision and reliability. We continually invest in the professional development of our workforce, ensuring that our team remains at the forefront of industry advancements and regulatory requirements. In line with our commitment to innovation, we invest heavily in in-house research and development (R&D) to continuously improve our ser vice offerings. This allows us to swiftly adapt to the challenges faced by the industry and develop new technologies that enhance the effec tiveness of our solutions. By doing so, we help our clients stay ahead of potential issues, contributing to the long-term sustainability and integrity of their pipeline assets. Our comprehensive approach to pipeline integrity management ensures that our clients can rely on us for complete solutions—from clean ing and inspection to ongoing maintenance and repair recommendations |

Get in Touch

Let’s Work Together to Ensure Your Pipeline’s Integrity

|

|

info@kahramann.co.id

technical_01@kahrmann.co.id |

Phone |

+62 811-8770-777

+62 852-4621-7936 +62 821-9995-7563 |

Address |

Sopo del Tower, Tower B lt. 17, Jl. Mega Kuningan Kota Jakarta Selatan, DKI Jakarta 12950

|